BLOW MOLDING | PLASTIC INJECTION | ROTOMOLDING | TECHNICAL PLASTIC PARTS

BLOW MOLDING | PLASTIC INJECTION | ROTOMOLDING | TECHNICAL PLASTIC PARTS

With its 120 collaborators, Tiag Industries keeps the assets of a human-scale company that will bring you reactivity and services.

Exercise every plastic transformation profession which are blowmolding, injection and rotomolding permits to answer to requirements from very numerous industrial sectors with tailored technical solutions, this in a tense flow if needed.

OUR FABRICATION PROCESSES

A technical plastic part is a part that has beforehand needed a study for defining the more adapted material compared to the aspect and the wished functionality, but also compared to the better tailored fabrication process.

It is a part on which a post-transformation machining could be realized: fitting of inserts (during or after the transformation process), collage of labels, assembling. It is an added value part, allying aspect, mechanical strength, dimensional tolerances, economical and industrial cost.

BLOWMOLDING

Blow molding is a molding process used in the manufacturing industry to create hollow objects made of plastic, this process allows production for medium and high quantity…

INJECTION

Molding by injection is a manufacturing process for producing parts by injecting molten material into a mold for large quantity…

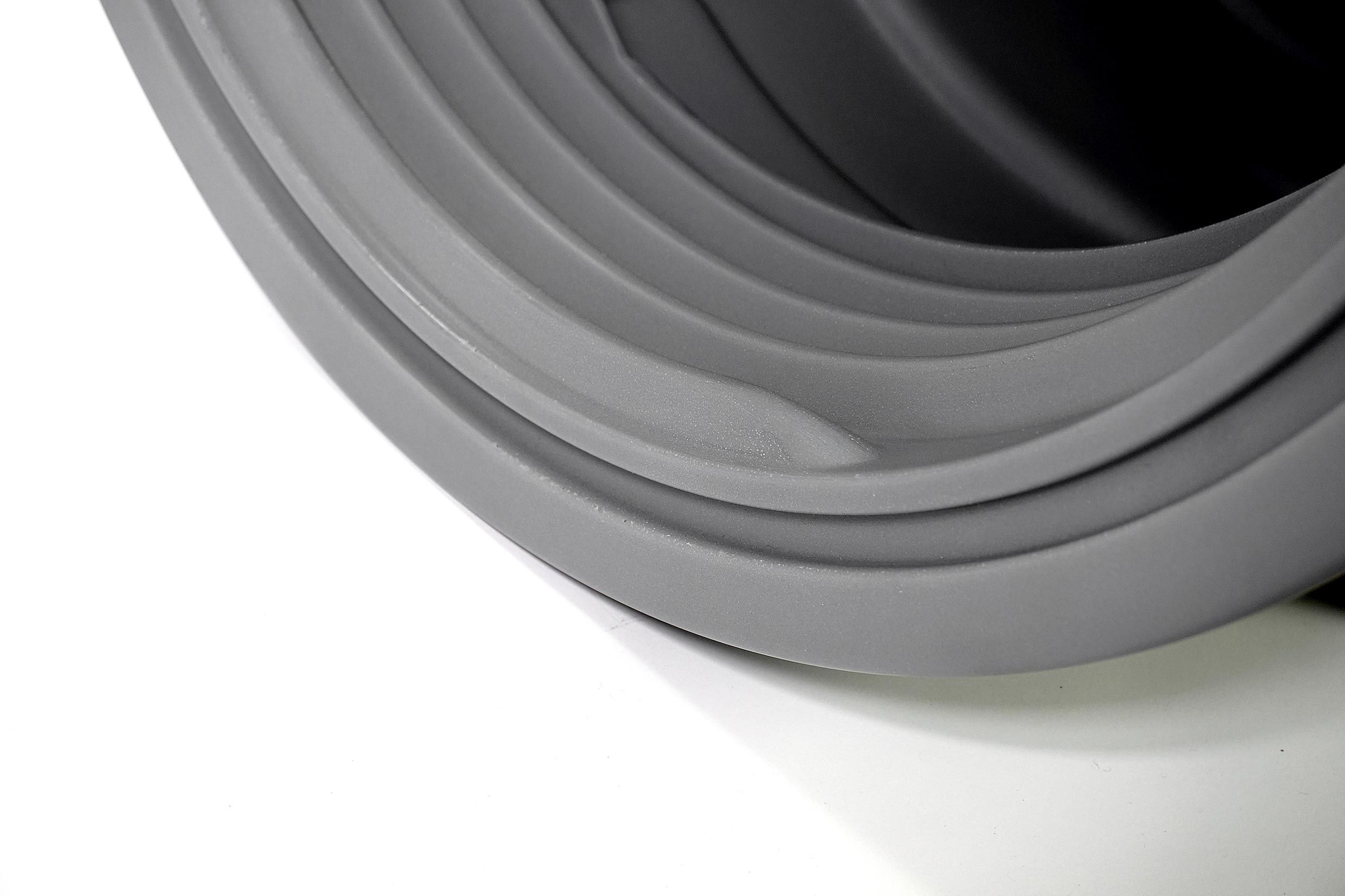

ROTOMOLDING

Rotomolding is a process of plastic material shaping into an oven. It produces hollow piece. This process is made for mal batch of production. We can easily overmold insert and perform twin sheet piece…

MACHINING AND ASSEMBLING

Tiag Industries owns a machining and finishing unity permitting so to bring an added value to our transformed products.