OUR

DESIGN OFFICE

Our integrated design office is composed with specialists, each having their competences in our three trades : blowmolding, injection and rotomolding.

Their complementarity in team work is an asset for answering to any kind of request.

Our design office accompanies you in all steps, from the prototype to the realization.

3D Modeling

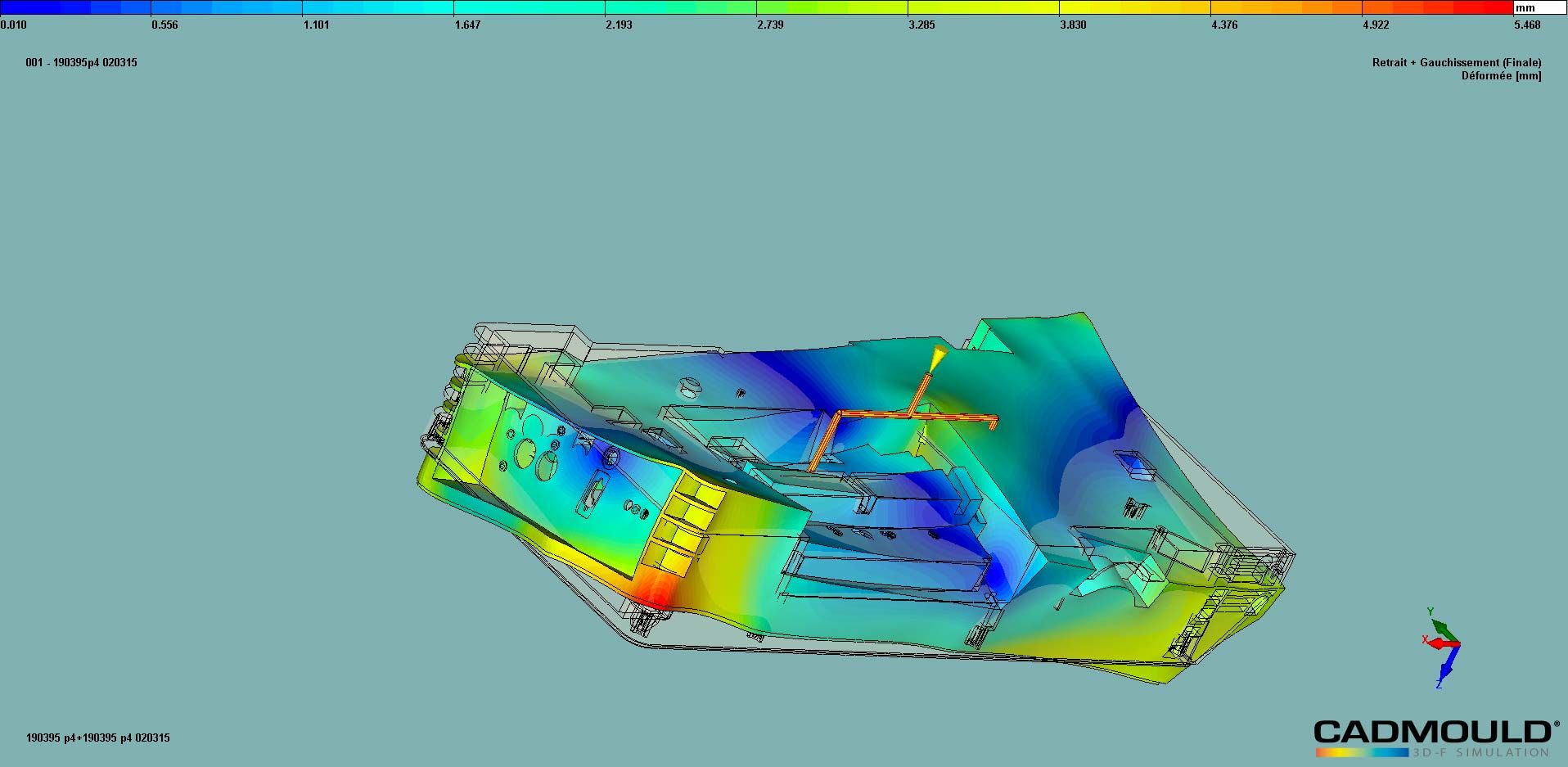

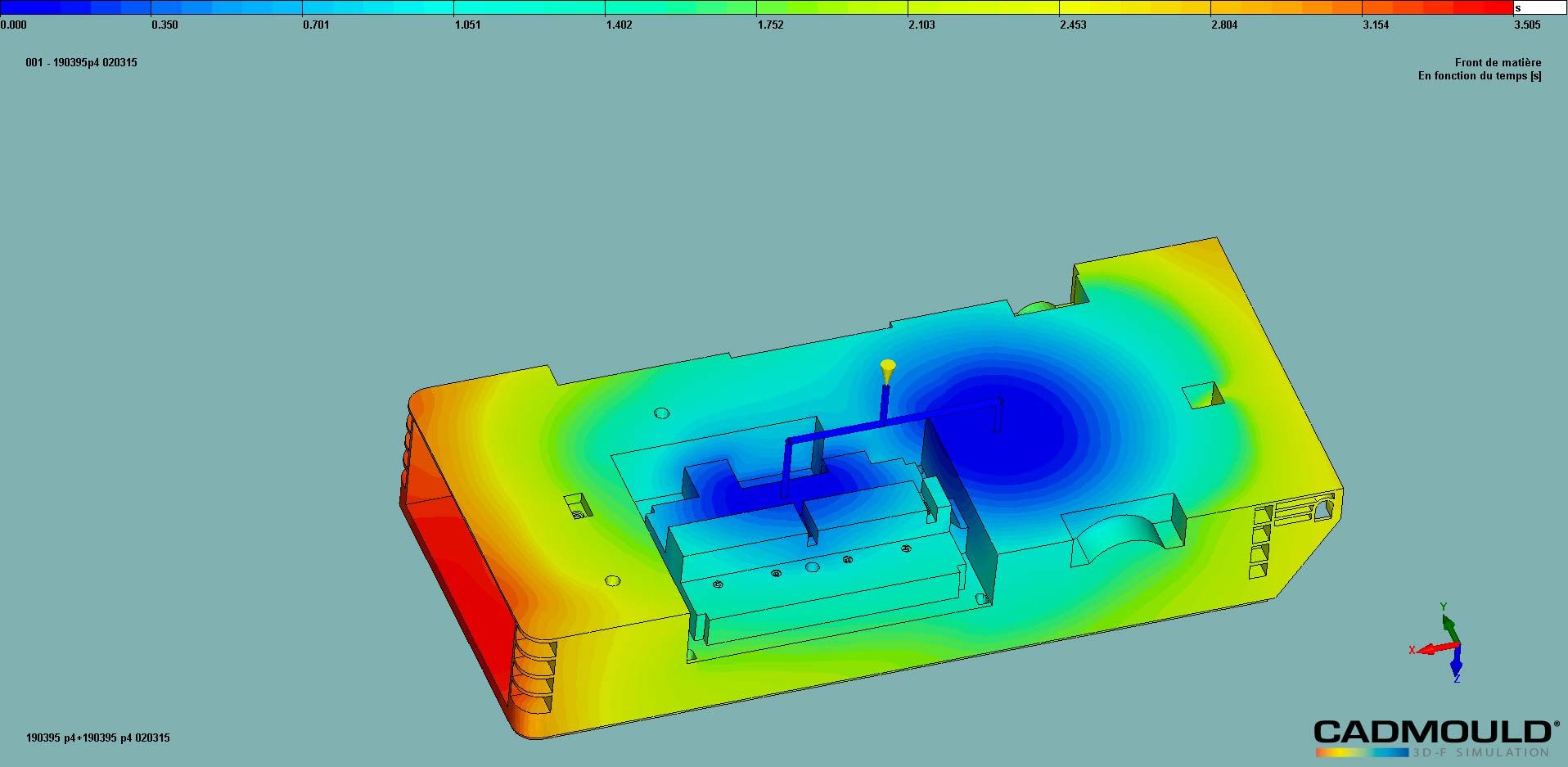

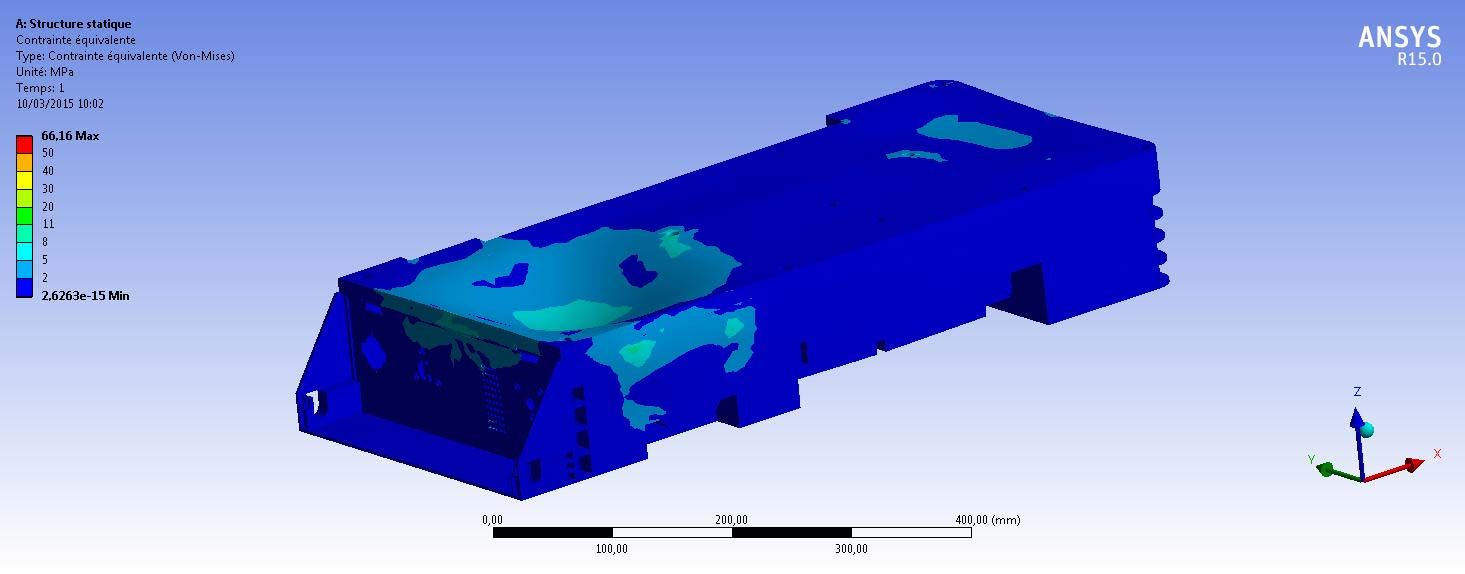

Calculation of finished elements

Definition of plastic and additive raw materials

Definition of molds and finishing devices

Prototypes realization

Softwares

SOLIDEDGE for products modeling

ANSYS for structures calculation

B-SIM for molding simulation

Matchings

UNIGRAPHICS

PROENGINEER

CATIA

EUCLID

IDEAS

AUTOCAD