PLASTIC

Rotomolding

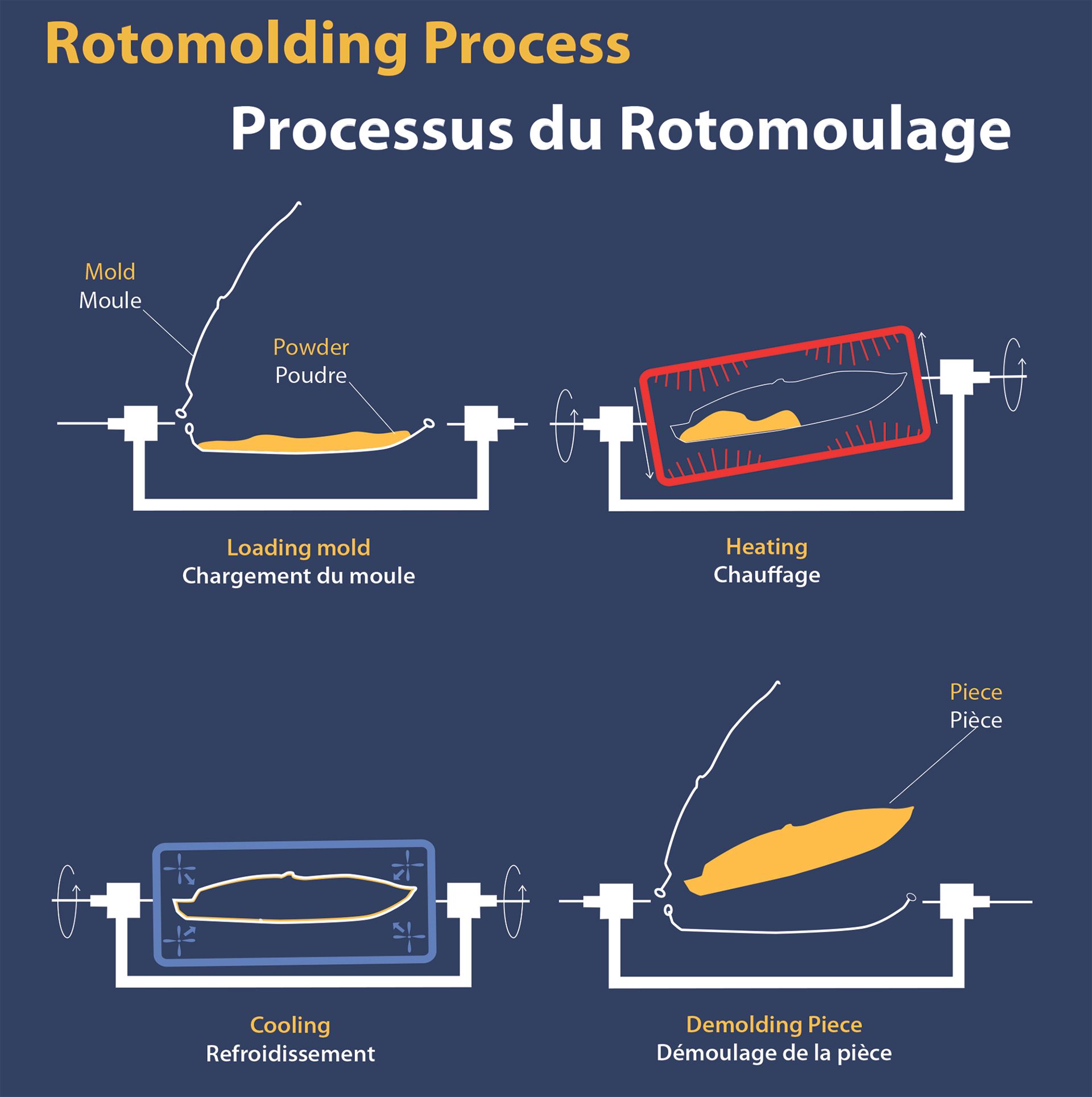

Rotomolding is a process of plastic material shaping into an oven. It transforms hollow parts.

This process permits to realize big parts with complex forms, to overmold inserts, to realize multilayers parts.

In the form of powder, plastic is charged into a mold in order to reproduce the inner shape of this mold’s, which volume’s capacity can goes from 0,1 to 50 000 liters. More used materials are the PE, but it is also possible to transform polypropylene, polycarbonate, polyamides.

Here are some of our parts in rotomolding

MACHINE PARK

One rotomolder sphere permitting to manufacture parts of approximately 3 meters long and with an weight of approximately 100kgs.

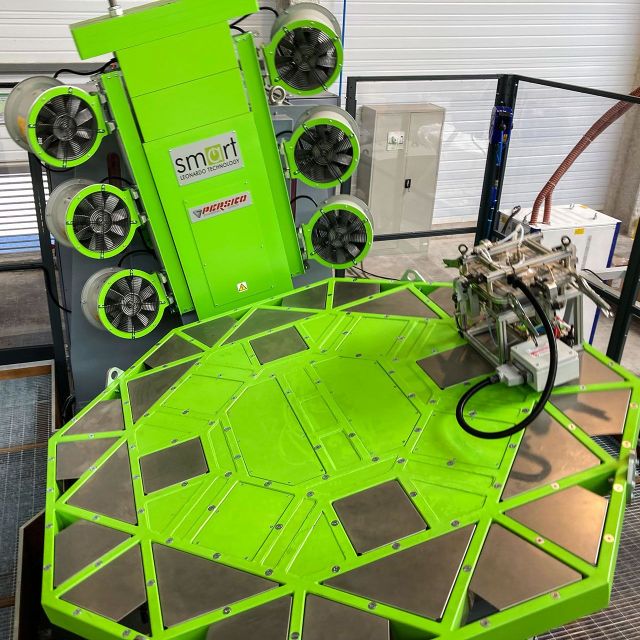

One SMART rotomolder of 3 meters long.

Also see

BLOWMOLDING

Blow molding is a molding process used in the manufacturing industry to create hollow objects made of plastic, this process allows production for medium and high quantity…

INJECTION

Molding by injection is a manufacturing process for producing parts by injecting molten material into a mold for large quantity…

MACHINING AND ASSEMBLING

Tiag Industries owns a machining and finishing unity permitting so to bring an added value to our transformed products.